Powder-Coating vs. Dye Sublimation for Vinyl Fittings: Which Finish Is Best?

Vinyl fittings play a key role in fencing and architectural systems, providing both structural support and a finished appearance. While the base material offers durability and low maintenance, the finishing method used on these fittings can significantly impact their look, longevity, and resistance to the elements. Choosing the right finish is essential for achieving the desired aesthetic while also ensuring long-term performance. Two of the most common finishing options are powder-coating and dye sublimation, each offering distinct benefits and characteristics.

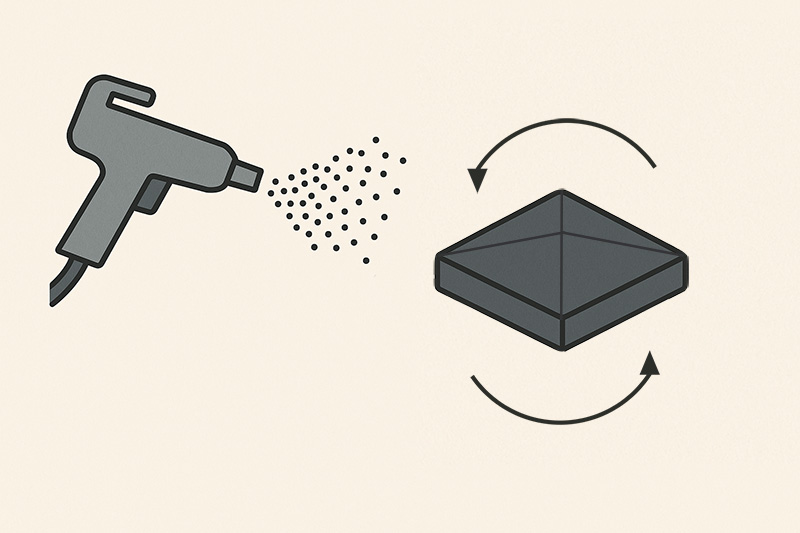

What is Powder-Coating?

Powder-coating is a finishing process that involves applying a dry powder to a surface and then curing it under heat to form a protective, decorative layer. This results in a smooth, even coating that adheres tightly to the material. It is commonly used on both vinyl and metal fittings in fencing, railing systems, and outdoor structures where durability and color retention are important.

Pros:

- Extremely durable and resistant to chipping, scratching, and fading

- Available in a wide range of solid colors and finishes

- Performs well in outdoor and high-traffic environments

Cons:

- Limited to solid colors and uniform textures

- Less flexibility for custom or natural-looking designs

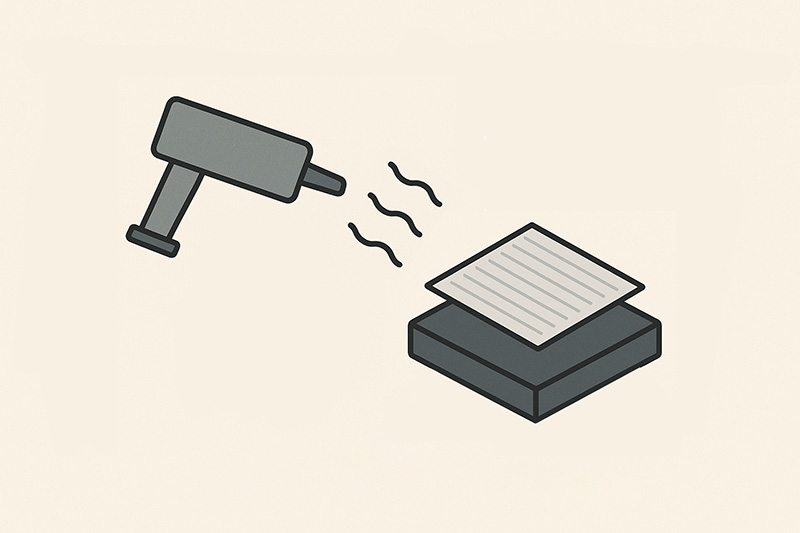

What is Dye Sublimation?

Dye sublimation is a finishing technique that uses heat to transfer ink directly into the surface of a material. The ink turns into gas and embeds into the coating, creating a smooth, vibrant finish that becomes part of the surface itself. This process is ideal for adding realistic woodgrain effects or custom patterns to vinyl fittings, giving them a visually rich appearance.

Pros:

- Delivers high-definition, lifelike patterns and textures

- Allows for full customization, including woodgrain and graphic designs

- Produces a smooth, integrated finish

Cons:

- May fade more quickly in direct sunlight unless UV protection is added

- Less resistant to scratching compared to powder-coated finishes

Key Differences Between the Two

- Appearance: Powder-coating offers solid, uniform colors, while dye sublimation provides realistic patterns and textures like woodgrain.

- Durability: Powder-coated surfaces are more abrasion-resistant and ideal for high-wear areas. Dye sublimated finishes may require a UV topcoat to maintain their appearance.

- Design Flexibility: Dye sublimation allows for greater customization and visual variety. Powder-coating is more limited to solid colors and standard finishes.

- Cost: Costs vary depending on the project. Powder-coating may be more economical for large runs, while dye sublimation can be more expensive for custom or detailed finishes.

- Environmental Resistance: Powder-coating typically holds up better in harsh weather conditions, while dye sublimation may need additional protection in extreme environments.

In summary, both powder-coating and dye sublimation provide effective finishing solutions for vinyl fittings, each with its own strengths. Powder-coating is preferred for its durability and uniform appearance, while dye sublimation stands out for its visual realism and custom design potential.

Best Use Cases

Choosing between powder-coating and dye sublimation depends on the specific goals of your project. Each finishing method excels in different scenarios, based on appearance, durability, and design needs.

When to Choose Powder-Coating:

- Projects that require a solid, uniform color with a clean finish

- Applications exposed to frequent wear, such as public fencing or commercial railings

- Environments with harsh weather conditions, including intense sun, rain, or snow

- Installations where low maintenance and long-term color retention are top priorities

When to Choose Dye Sublimation:

- Projects that require a realistic woodgrain appearance or other custom patterns

- Architectural features that prioritize aesthetics and design flexibility

- Residential or decorative fencing where a natural look enhances curb appeal

- Installations where a smooth, integrated texture is preferred over a painted surface

Powder-Coated Versus Dye Sublimation Recap

Both powder-coating and dye sublimation offer effective finishing solutions for vinyl fittings, but the best choice depends on the application. Powder-coating is ideal for achieving strong, uniform finishes that can endure tough environments with minimal upkeep. Dye sublimation, on the other hand, brings visual richness and design flexibility, making it a great choice for projects that prioritize appearance and customization. Understanding the strengths of each method helps ensure your fittings not only perform well, but also match the vision and style of your space.

Shop Vinyl Fence Fittings

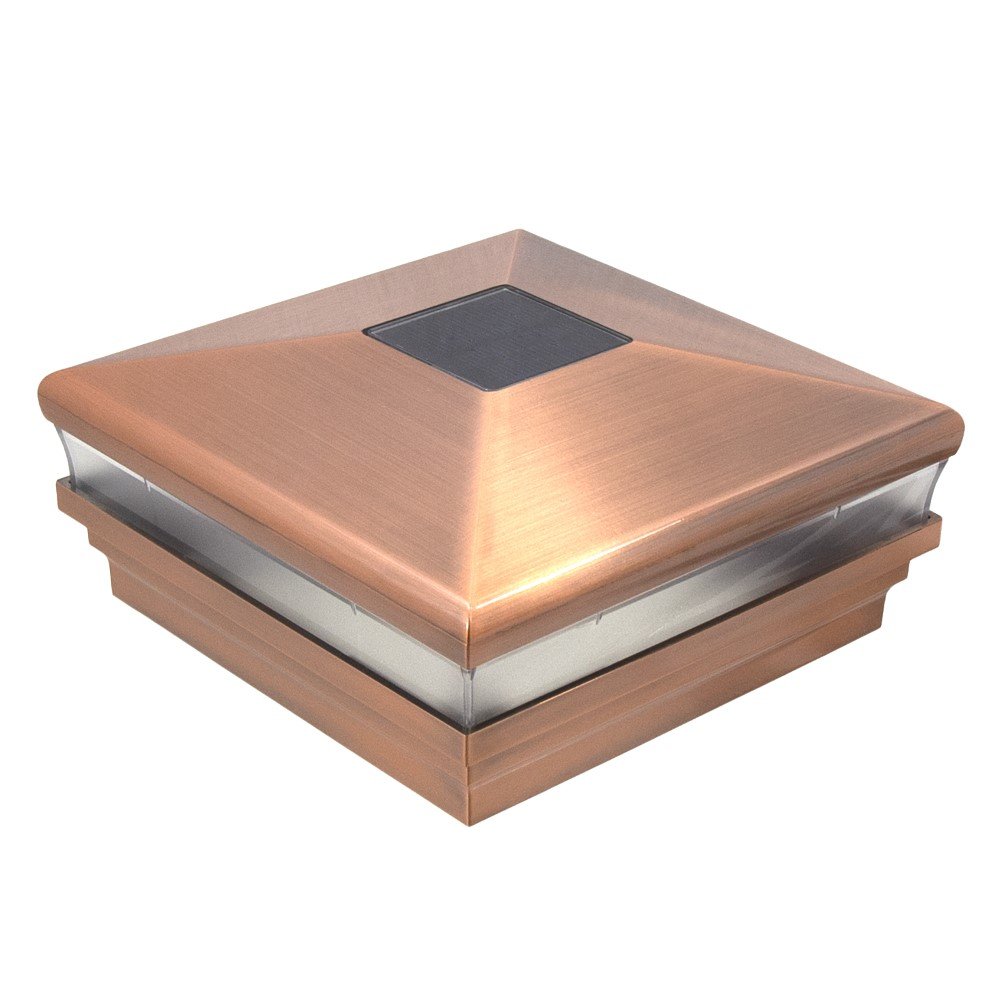

Solar Post Caps

Shop Now

Low-Voltage Post Caps

Shop Now

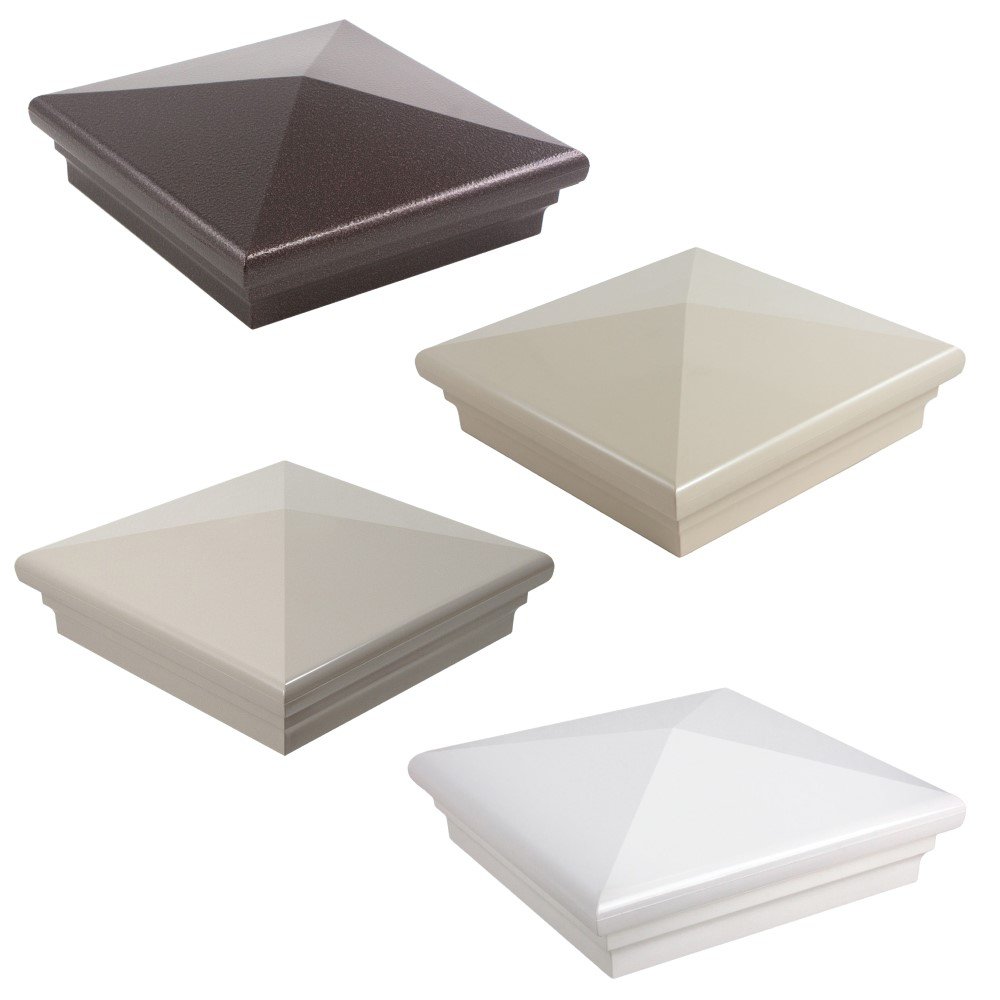

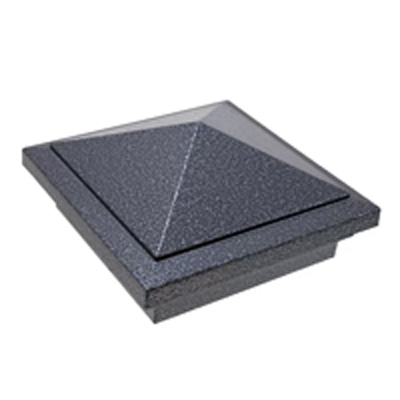

Vinyl Post Caps

Shop Now

Post Skirts

Shop Now

Accessories

Shop NowIf you have any further questions about vinyl fencing and fittings, please do not hesitate to reach out. We are always happy to help!

Contact Us